-

QUALITY MACHINECommited to Deliver

QUALITY MACHINECommited to Deliver -

QUALITY MACHINECommited to Deliver

QUALITY MACHINECommited to Deliver

About

SUKAN CENTRIMACH LLP

SUKAN CENTRIMACH LLP has been started in Technical Collaboration with Tulsa Centrifugal CastingMachine, USA as an authorised manufacturer to manufacture Centrifugal Casting Machines.

The Company is an upcoming company who is making rapid strides to achieve full recognition inmanufacturing high quality machines, comparable with those which were being imported from variousdeveloped countries and gained acknowledgement in several core sector industries of nationalimportance.

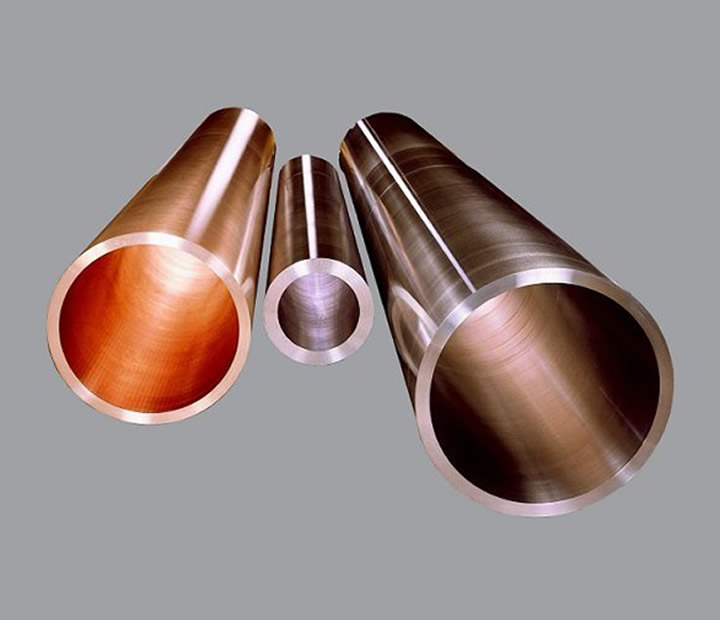

We also manufacture ancillary products required for Centrifugal Castings like Moulds and Mould Wash.

OUR PRODUCTS

Horizonal Machine

There are several basic machine sizes available starting with our 5K, 10K, 15K, 30K, 50K and 100K series. Depending on the model, these machines can produce up to a total load rating of 100,000 lbs (45360 kgs).

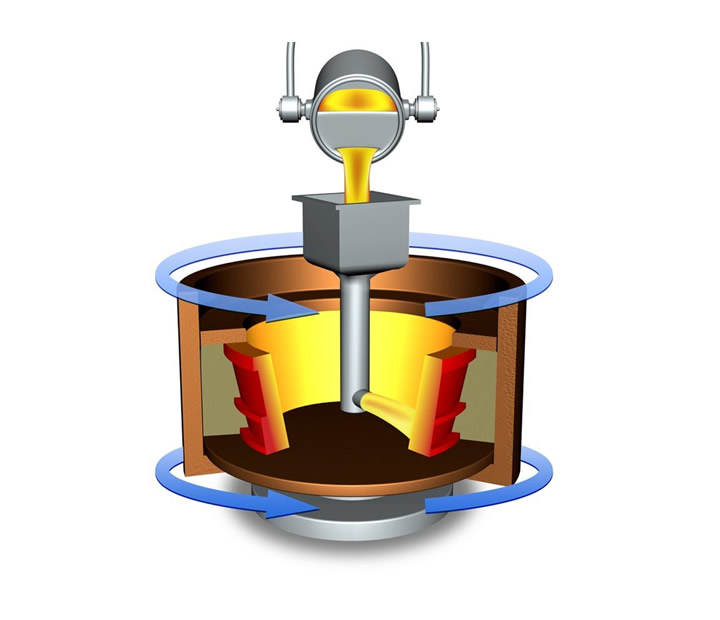

Vertical Machine

True Centrifugal, Semi-Centrifugal, and Centrifuge (pressure castings) can be produced using Vertical Centrifugal Casting machines. From simple bushings to complex parts, they offer the most diversified method

Babbiting Machines

Horizontal & Vertical Centrifugal Babbitt Lining Machines available in a variety of sizes from Bench top models to large floor models capable of producing single piece or split shell Babbitt bearings.

Check Out Our Latest Blogs

Overview of Centrifugal Casting

Centrifugal casting is a process that delivers components of high material soundness. As a result, it is the technology of choice for applications like jet engine compressor cases, hydro wear rings, many military products, and other high-reliability applications. It has also proven to be a cost-effective means of providing complex shapes with reduced machining requirements and lower manufacturing costs as compared to forgings and fabrications.

What Is Centrifugal Casting?

Centrifugal casting provides high material soundness and is the metal casting process of choice for jet engine compressor cases, petrochemical furnace tubes, many military and defense components, and other applications requiring high reliability. Some manufacturers produce centrifugal components, including some with O.D shaping, in dies rotating about the vertical axis.

Vacuum Centrifugal Casting

Centrifugally casting in a vacuum is used when part detail and control of exposure to the atmosphere is critical since some alloys, including nickel-cobalt super alloys, are reactive to oxygen. In addition to the advantages of casting in a vacuum, the inherent high metal integrity delivered by centrifugal casting is realized, including directional solidification, absence of porosity, and net-shaping. Vacuum centrifugal casting provides products with